Ever feel like your product development process is all over the place? Files in a dozen folders, feedback in email threads, and version chaos that keeps teams guessing? You’re not alone. As product lines become more complex and timelines shrink, having a central command center is no longer a nice-to-have, it’s essential.

Table of Contents

That’s where Product Lifecycle Management (PLM) software comes in.

In this guide, we’ll break down exactly what PLM is, why it’s so important today, who should be using it, and what benefits and features to look for. We’ll also highlight the top PLM tools in 2025, so by the end, you’ll know how to find the right fit for your business.

What is Product Lifecycle Management (PLM)?

PLM stands for Product Lifecycle Management—a strategic process that manages everything about a product from the spark of an idea all the way to the final version shipped to customers (and sometimes beyond). It connects design, development, sourcing, and quality teams under one digital roof to keep everything running smoothly and visibly.

Why PLM Software is Critical for Modern Product Development

Modern product development moves fast. With global teams, complex supply chains, and constant updates, relying on spreadsheets and email threads just doesn’t cut it anymore. PLM software helps businesses centralize product data, streamline processes, and reduce costly delays or missteps. It gives teams a real-time window into every part of a product’s lifecycle.

Who Should Use PLM Software?

PLM software isn’t just for massive manufacturers. It’s used by fashion brands, consumer goods companies, regulated industries like pharma or aerospace, and even direct-to-consumer (DTC) brands. If your team handles product specs, compliance, suppliers, or design files, PLM software can help you do it better, faster, and with fewer mistakes.

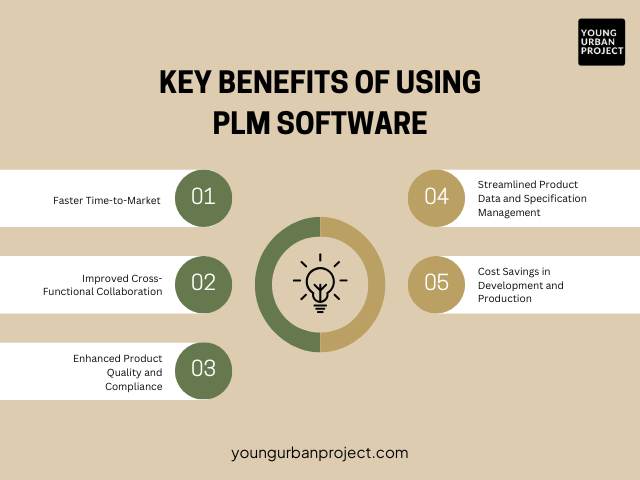

Key Benefits of Using PLM Software

1. Faster Time-to-Market

By connecting departments and automating workflows, PLM software cuts down on unnecessary steps and delays. Everyone works off the same data in real time, so product teams can move from idea to launch more quickly, with fewer errors slowing things down.

2. Improved Cross-Functional Collaboration

PLM tools break down silos between departments like design, engineering, quality, and marketing. Shared dashboards and task automation help keep everyone aligned, reducing miscommunication and duplication of work, especially when teams are spread across geographies or time zones.

3. Enhanced Product Quality and Compliance

With built-in quality checks, approval workflows, and audit trails, PLM software ensures that every product meets internal standards and regulatory requirements. It helps flag issues early and keeps documentation organized for inspections or certifications.

4. Streamlined Product Data and Specification Management

PLM software stores every product-related file, like CAD drawings, material specs, tech packs, and BOMs—in one central location. This makes it easier to manage, update, and share accurate information across teams without version confusion.

5. Cost Savings in Development and Production

Fewer errors, faster iterations, and better design reuse add up to serious cost savings. PLM systems also help avoid expensive rework and make it easier to manage material costs, vendor quotes, and production efficiencies.

Also Read: 15 Best WhatsApp Marketing Software Tools

Core Features to Look for in a PLM Tool

1. Centralized Product Data Management

This is the heart of any good PLM. All product-related data—from design files to testing reports—should live in one place. It keeps teams on the same page and ensures that only the most current information is used in decision-making.

2. Workflow Automation & Change Management

The best PLM tools automate routine approvals, alerts, and tasks. They also provide clear visibility into design or spec changes—who made them, when, and why—so teams don’t waste time chasing updates or making mistakes on outdated info.

3. BOM (Bill of Materials) Tracking

PLM software lets you build and manage BOMs with accuracy. Whether you’re dealing with hardware parts or garment components, clear and structured BOMs reduce confusion between product development, procurement, and manufacturing teams.

4. Quality & Compliance Management

Look for tools that include features like CAPA (Corrective and Preventive Actions), document control, and compliance workflows. This ensures your products meet both internal and external standards—especially in industries with strict regulations like pharma or aerospace.

5. Supplier Collaboration

A solid PLM solution enables secure collaboration with external vendors and suppliers. Teams can share tech packs, receive feedback, and track changes without endless email threads. It shortens lead times and strengthens supplier relationships.

6. Integration with ERP, CAD, and Supply Chain Tools

PLM works best when it plays well with others. Make sure your PLM software integrates with your ERP system, CAD tools, and supply chain platforms. This way, product data flows smoothly from design to sourcing to production.

7. Version Control & Audit Trails

No one likes guessing which version is the latest. PLM tools track every change made to a product’s file or spec. With full audit trails, teams can trace what happened, when it happened, and who did it—critical for accountability and compliance.

Top Product Lifecycle Management Software in 2025

A. Enterprise-Grade PLM Solutions

1. Oracle Fusion Cloud SCM (PLM Module)

Oracle’s PLM offering is part of its broader SCM suite and is designed for enterprises with complex supply chain operations. It helps teams manage product development, engineering changes, and compliance across global operations—all within a unified cloud platform.

- End-to-end product development lifecycle management

- Built-in integration with Oracle ERP and SCM modules

- Engineering change orders and product structures

- Role-based access and secure global collaboration

- Detailed audit trails for compliance and traceability

2. Infor CloudSuite PLM for Process (Optiva)

Optiva is purpose-built for process manufacturers like food, chemical, and pharmaceutical companies. It supports formulation management, regulatory compliance, and faster innovation, all with deep industry-specific features baked in.

- Centralized formula and recipe development

- Built-in support for FDA, REACH, GHS, and other standards

- Labeling, packaging, and claims management

- Raw material and supplier tracking

- Integrated analytics and reporting tools

B. Cloud-Native & Versatile Platforms

3. Arena PLM (by PTC)

Arena is a cloud-native PLM trusted by startups and mid-market manufacturers alike. It’s especially popular in medical devices, electronics, and high-tech industries thanks to its flexibility and built-in compliance tools.

- Complete product record and BOM management

- Quality process integration (CAPA, NCMR)

- Supplier collaboration tools

- Cloud-based with role-specific permissions

- Integrates with ERP, CAD, and Jira

4. KloudPLM

KloudPLM runs natively on Salesforce, making it a smart choice for companies already using the platform. It combines robust PLM features with CRM-style analytics and dashboards for greater visibility into product health.

- Salesforce-native architecture for easy scalability

- Lifecycle stages, project tracking, and task assignments

- Visual dashboards with real-time data insights

- Supplier and document collaboration features

- Built-in change control and user permissions

5. Specright

Specright is built around the idea that great products start with great specifications. It’s ideal for CPG, packaging, and food companies that need to manage formulas, materials, and sustainability data at scale.

- Spec-first data structure (packaging, formulas, SKUs)

- Supplier collaboration and quality tracking

- ESG and sustainability metric integration

- Document workflows and audit trails

- Easy import/export from Excel-style interfaces

C. Fashion & Consumer Goods Focused PLMs

6. WFX PLM

WFX is made for fashion and consumer brands looking to manage design, production, and sourcing from a single cloud platform. It’s mobile-friendly and easy to adopt across global vendor networks.

- Digital tech packs and sample workflows

- Calendar and milestone tracking

- Supplier portals with real-time updates

- Visual product library and fabric database

- eCommerce and ERP integrations

7. Techpacker

Techpacker is a favorite among independent designers and agile fashion teams. Its drag-and-drop tech pack builder simplifies the entire sampling process while keeping everything organized visually.

- Visual, card-based tech pack creation

- Custom measurement tables and specs

- Factory-ready PDF exports

- Collaboration with manufacturers via comments

- Illustrator plugin for seamless design integration

8. BlueCherry PLM

BlueCherry is built for apparel and footwear brands with complex sourcing and supply chain needs. It offers detailed control over styles, BOMs, vendors, and seasonal calendars.

- Line planning and style development tools

- Costing, sourcing, and sample management

- Integrated with ERP and CAD platforms

- Vendor communication and approval workflows

- Calendar and milestone tracking

Enroll Now: Live Product Marketing Course

9. ApparelMagic

ApparelMagic blends PLM and inventory management for fashion brands, making it a go-to choice for small to mid-sized labels. Its focus on visual tools and ease of use stands out.

- Visual line sheets and digital spec sheets

- Inventory and order tracking built-in

- Fabric and vendor database

- Workflow automation and status tracking

- eCommerce integration for DTC brands

10. Style Arcade

While not a traditional PLM, Style Arcade supports assortment planning and inventory management for fashion retailers. It’s ideal for buyers and planners working closely with design teams.

- Real-time collection performance analytics

- Visual assortment planning tools

- SKU-level inventory visibility

- Sales forecast modeling

- Supports buying, planning, and merchandising workflows

11. Exenta PLM

Exenta delivers an end-to-end PLM system focused on the apparel industry. It supports product development, sourcing, and compliance, all within a unified, mobile-accessible platform.

- Collaborative product design workflows

- Raw material, trim, and color libraries

- Real-time vendor collaboration

- Costing and production tracking

- Mobile-friendly interface

12. PolyPM

PolyPM brings ERP and PLM together for apparel and textile manufacturers. It’s a powerful tool for brands looking to manage operations and development in one system.

- Unified PLM and ERP system

- Material and style development

- Inventory and purchase order tracking

- Supplier and vendor communication

- Product costing and WIP tracking

13. Backbone PLM

Backbone is a lean, modern PLM designed for fast-growing DTC brands and eCommerce retailers. It focuses on making tech packs, costing, and vendor workflows simple and fast.

- Lightweight tech pack builder

- BOM, cost sheet, and sourcing tools

- Ideal for fashion, home goods, and accessories

- Clear collaboration channels for suppliers

- Drag-and-drop design asset management

D. Regulated & Compliance-Heavy Industries

14. Dot Compliance

Dot Compliance is tailored for life sciences companies that need fast, reliable, and compliant PLM systems. It comes with built-in templates and pre-validated workflows to get started quickly.

- FDA and GxP-ready out of the box

- CAPA, audit, and deviation management

- Electronic signatures and document control

- Easy configuration for non-technical users

- Cloud-based and scalable

15. Trace One PLM Suite

Trace One serves CPG, private label, and large retail brands with a strong focus on compliance, specification management, and traceability across global product lines.

- Labeling, packaging, and ingredient tracking

- Built-in regulatory compliance checks

- Supplier onboarding and document control

- Cloud-based access for retailers and manufacturers

- Detailed audit and approval trails

How to Choose the Right PLM Software for Your Business

1. Match PLM Capabilities to Your Industry Needs

Not every PLM tool fits every business. A fashion brand needs tech pack and supplier collaboration features, while a chemical company may need formulation tracking and compliance tools. Start by identifying what your industry requires and shortlist tools built to handle those specific workflows.

2. Cloud vs On-Premise Considerations

Cloud-based PLMs are more flexible and cost-effective, especially for teams working remotely or across time zones. On-premise might make sense if you have strict IT or security policies, but for most growing businesses today, cloud is the smarter, more scalable choice.

3. Budget, Scalability & User Adoption

Avoid choosing a tool that’s either overbuilt or underpowered. Think about your team size now—and where you’ll be in a few years. Also, consider how easy it is for your team to adopt the system. Even great software fails if no one wants to use it.

4. Integration with Existing Systems (ERP, CAD, SCM)

Your PLM should play nicely with the tools you already use. Integrating with ERP helps manage costs and procurement, while CAD integration supports your design process. If the PLM doesn’t connect easily, you’ll risk silos and slowdowns instead of efficiencies.

5. Regulatory Compliance Requirements

If you’re in a regulated space—like pharma, aerospace, or food—make sure the PLM supports your compliance needs. Look for audit trails, document control, e-signatures, and industry certifications. These features can save you huge headaches (and penalties) later on.

PLM Software Implementation Best Practices

1. Involve Cross-Functional Stakeholders Early

Don’t let IT or one department lead everything. Involve product, sourcing, design, quality, and even finance teams early in the process. That way, you get input from everyone who will actually use the system—and you’re more likely to get buy-in.

2. Clean Up and Migrate Data Carefully

Before migrating, review your existing product data. Clean it, standardize formats, and remove old junk. A messy database carried into a new PLM system will only cause confusion. Good data going in = better results coming out.

3. Prioritize User Training and Change Management

Even the best PLM won’t work if your team doesn’t understand how to use it. Set aside time for hands-on training. Create internal champions and be ready to support the team through the learning curve—it’s part of the process.

4. Define KPIs to Track Success Post-Implementation

You won’t know if the PLM is working unless you track the right metrics. Think: time-to-market, number of revisions, error rates, or cost savings. Set a baseline before go-live and check in regularly to measure impact.

PLM Software Trends to Watch in 2025

1. AI-Driven Product Insights and Automation

AI is starting to make PLM smarter—helping with demand forecasting, automatic spec validation, and even material selection. In 2025, more PLM tools are integrating AI to help teams make faster, data-backed decisions.

2. More Vertical-Specific PLM Offerings

Rather than one-size-fits-all platforms, we’re seeing more PLM tools built specifically for industries like fashion, pharma, or consumer goods. These solutions come with tailored workflows and language that feel more familiar to users from day one.

3. Tighter Integration with Sustainability Metrics

As sustainability becomes a core business goal, PLM tools are evolving to track carbon emissions, ethical sourcing, and material impact. Teams can now build sustainability into product decisions—not just track it as an afterthought.

Also Read: Green Marketing Examples: 15 Brands Promoting Sustainability

4. Increased Adoption by DTC Brands and SMEs

Smaller brands and DTC players are jumping on PLM to stay competitive. Lightweight, cloud-based tools now make it affordable and accessible for companies that previously felt priced out or overwhelmed by traditional systems.

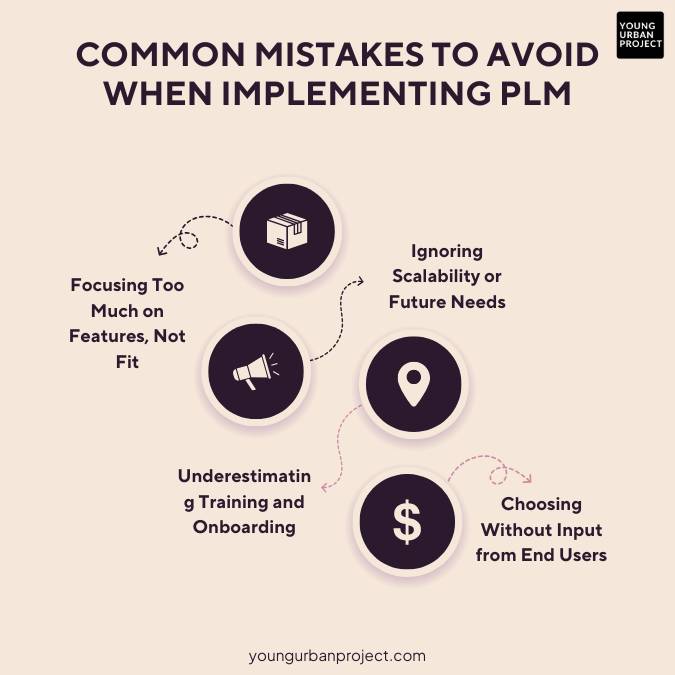

Common Mistakes to Avoid When Choosing or Implementing PLM

1. Focusing Too Much on Features, Not Fit

It’s easy to get distracted by feature lists. But a long checklist doesn’t matter if the tool doesn’t fit your workflow. Focus on how well the system supports your processes—not how many bells and whistles it claims to have.

2. Ignoring Scalability or Future Needs

Your company may grow faster than you expect. Make sure the PLM can scale with more users, products, or locations. A system that works for 10 users now should still work for 50 down the road.

3. Underestimating Training and Onboarding

A PLM rollout is more than a software install—it’s a mindset shift. Don’t assume your team will “figure it out.” Plan for dedicated training, internal support, and a few bumps during the adjustment phase.

4. Choosing Without Input from End Users

The people using the software every day should have a say in which system gets picked. Their feedback ensures the tool actually solves real problems—and avoids wasting money on something no one enjoys using.

Conclusion

Choosing the right PLM software isn’t just an IT decision—it’s a strategic investment that impacts your entire product development ecosystem. As markets move faster and competition intensifies, the companies that thrive will be those that eliminate development friction and accelerate innovation. Whether you’re a fashion brand struggling with tech packs or a manufacturer drowning in compliance documentation, modern PLM solutions offer a path forward.

The key is finding the right fit for your specific industry needs and growth stage. Don’t be dazzled by features you’ll never use, but don’t skimp on capabilities that could become critical as you scale. Remember that successful implementation hinges on team buy-in and proper data migration. With the right PLM partner, you’ll wonder how you ever managed without that single source of product truth keeping everyone aligned and moving forward.

FAQs: Product Lifecycle Management Software

1. What is the difference between PLM and ERP?

PLM manages a product from concept to manufacturing. ERP handles business resources like finance, inventory, HR, and logistics. They often work together but serve very different purposes.

2. Is PLM software only for manufacturers?

No. Fashion brands, pharma companies, food producers, and even DTC startups all use PLM to manage design, sourcing, and compliance.

3. Can small businesses use PLM software?

Yes. Tools like Techpacker, Backbone, and WFX are designed for smaller teams with simple interfaces and affordable pricing.

4. How long does it take to implement PLM software?

It depends on how complex your data and workflows are. Some tools take a few weeks to implement; others can take several months.

5. Is cloud PLM better than on-premise PLM?

For most businesses, yes. Cloud PLMs are easier to scale, access remotely, and update without needing heavy IT involvement.

6. Can PLM help with sustainability and compliance?

Absolutely. Many PLM systems now include modules for tracking sustainability metrics, regulatory data, and supplier certifications.